Our services

geo-c works together with planning offices, architectsand executing companies that need a high-performance

partner for the implementation of the hydraulic system

from the geothermal probes or collectors to the heat pump.

Furthermore, our technicians carry out service, maintenance

and repair work on the systems.

Planning aids and production

- Arrangement and design of the piping system

- Pre-assembly of hydraulic components

- Design and manufacture of individual system parts

Service, maintenance and repair work

- Commissioning and checking the hydraulic system

- Performance analysis with hydraulic balancing

- Retrofits and repairs

- Maintenance and Service

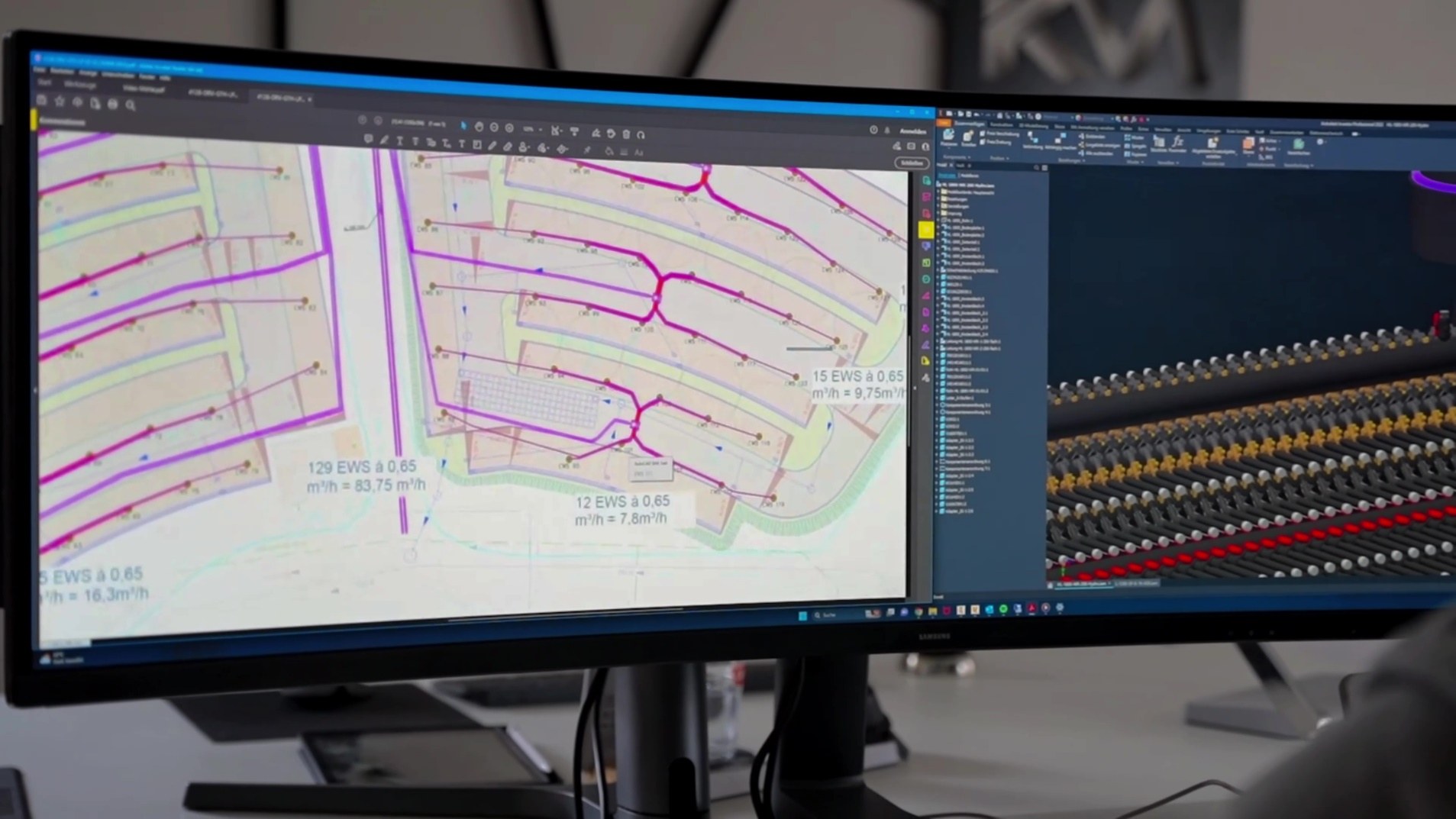

Arrangement and design of the piping system

The combination of the individual energy fields up to the heat pump is an important part of the system. A well-thought-out positioning of the distribution units with the appropriate pipe cross-sections for each individual project is the basis for a highly efficient geothermal system.Pre-assembly of hydraulic components

Here we support our partners in calculating and selecting the hydraulically relevant fittings that have proven to be suitable in practice. In this planning phase, we create the basis for optimally using the energy storage from the ground for cooling and heating operations.Design and manufacture of individual system parts

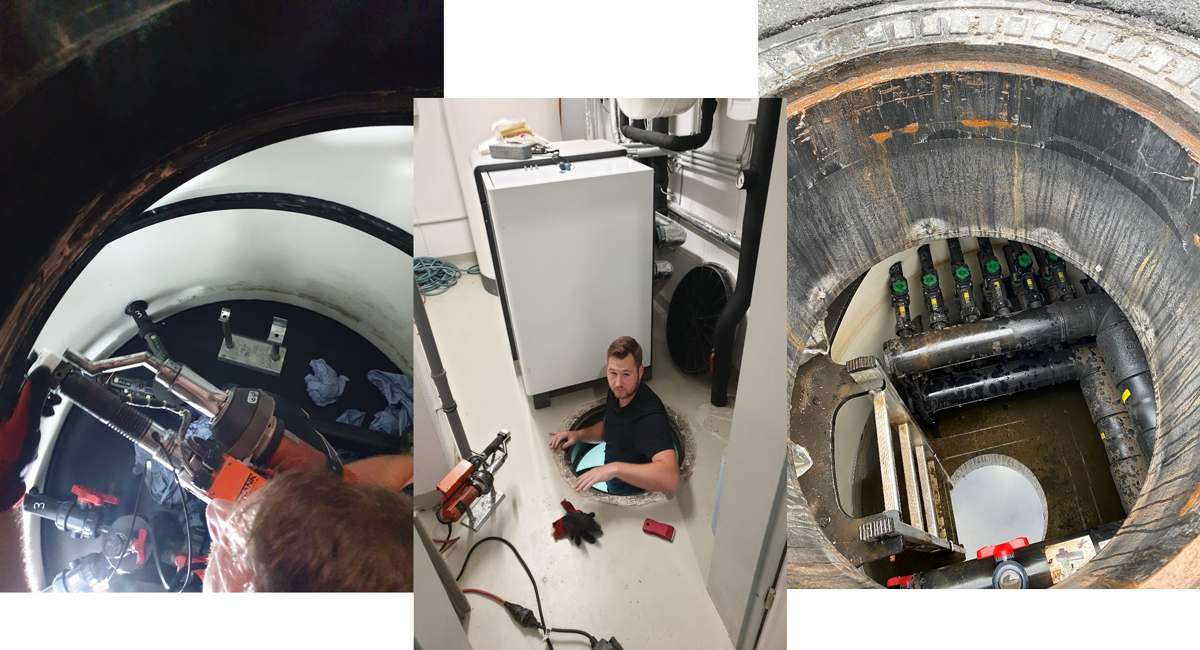

Once the required pipelines, distributors and fittings have been designed, the system components are put together. As a rule, the products from our extensive standard range can be configured accordingly. For larger projects, individual solutions are usually used that are specifically designed and produced by us for this construction project.Commissioning and checking the hydraulic system

At the request of our customers, we take over the initial commissioning of the system. The work usually takes place in coordination with the company that installed the heat pump system. Here the entire primary line system is passed through. The system is checked for leaks, flow and any air inclusions, which often lead to heat pump malfunctions during the start-up period. Furthermore, the heat transfer fluid is checked for concentration and homogeneity.Performance analysis and hydraulic balancing

All geothermal probes and collectors connected to the geothermal field are assigned to a power potential and then hydraulically balanced accordingly. This usually takes place during commissioning and then again at the end of the first heating period.Retrofits and repairs

Our fitters are also on duty to repair defective system components and, if necessary, bring them up to date with the latest technology to ensure error-free operation.System inspection and maintenance

One of the tasks geo-c has set itself is to continue to support the numerous projects it has been involved in after completion. It quickly became clear that although a geothermal system can be operated with very little maintenance, a check interval is usually of great benefit. Most of the tested trouble-free systems have a significantly higher energy potential.

energy-control ec-100

Remote maintenance and optimization of the energy flow, control of the cold and heat storage and a targeted adjustment of the performance potential. These possibilities are provided by the intelligent ec-100 system, which can be integrated into our components as a complete unit.